Revolutionizing Manufacturing: The Power of 3D Printing

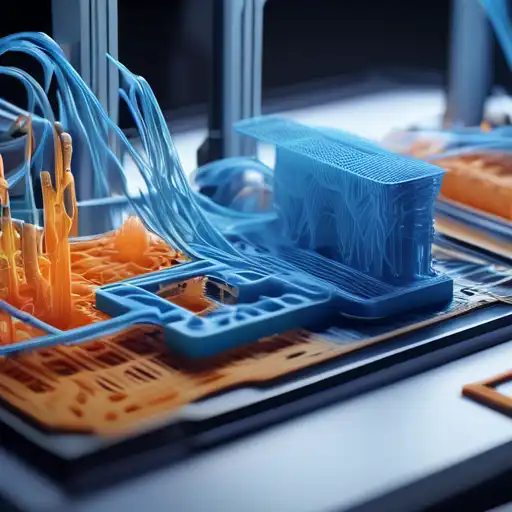

3D printing, also known as additive manufacturing, is transforming the way we create objects, from simple household items to complex industrial components. This groundbreaking technology builds objects layer by layer, offering unparalleled flexibility in design and production. In this article, we explore how 3D printing is shaping the future of manufacturing and beyond.

The Basics of 3D Printing

At its core, 3D printing involves creating a three-dimensional object from a digital file. The process starts with designing a model using computer-aided design (CAD) software. The printer then reads the design and deposits material, layer by layer, until the object is fully formed. This method allows for the production of shapes and structures that would be impossible or prohibitively expensive to make with traditional manufacturing techniques.

Applications of 3D Printing

The applications of 3D printing are vast and varied. In the medical field, it's used to create custom prosthetics and even organs. In aerospace, companies are printing parts for aircraft and spacecraft, reducing weight and saving fuel. The automotive industry uses 3D printing for both prototyping and manufacturing parts. Even the fashion industry has embraced this technology, printing everything from shoes to dresses.

- Medical Innovations: Custom prosthetics and bioprinting of tissues.

- Aerospace Advancements: Lightweight components for aircraft.

- Automotive Efficiency: Rapid prototyping and part manufacturing.

- Fashion Forward: Unique, printed clothing and accessories.

The Environmental Impact

3D printing also offers significant environmental benefits. By building objects layer by layer, it minimizes waste compared to subtractive manufacturing processes. Additionally, the ability to print on demand reduces the need for inventory and the carbon footprint associated with shipping products worldwide. However, the sustainability of 3D printing depends on the materials used and the energy efficiency of the printers.

Challenges and Future Directions

Despite its potential, 3D printing faces challenges, including high costs for industrial-grade printers and limitations in material choices. However, ongoing research and development are addressing these issues, paving the way for more widespread adoption. The future of 3D printing includes the possibility of printing food, buildings, and even more complex biological structures.

As 3D printing technology continues to evolve, its impact on manufacturing, design, and various industries will only grow. By enabling customization, reducing waste, and opening up new possibilities for innovation, 3D printing is truly creating the future layer by layer.

For more insights into the latest technological advancements, check out our articles on innovation in technology and the future of manufacturing.