Introduction to IoT in Industrial Automation

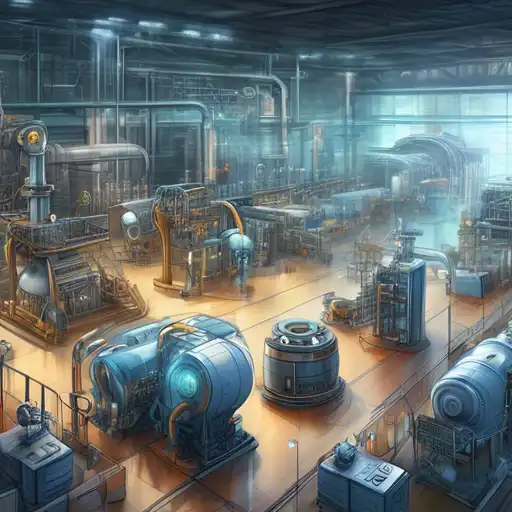

The Internet of Things (IoT) is transforming industrial automation by enabling smarter, more efficient manufacturing processes. By connecting machines, devices, and systems, IoT facilitates real-time data exchange, leading to unprecedented levels of automation and control.

Key Benefits of IoT in Industrial Automation

IoT brings numerous advantages to industrial automation, including:

- Enhanced operational efficiency through real-time monitoring and control

- Reduced downtime with predictive maintenance

- Improved safety by monitoring hazardous conditions

- Greater flexibility in manufacturing processes

Real-World Applications

From smart factories to automated supply chains, IoT is making its mark. For instance, sensors can predict equipment failure before it happens, minimizing unplanned downtime. Similarly, IoT-enabled devices streamline inventory management, ensuring materials are always available when needed.

Challenges and Considerations

Despite its benefits, integrating IoT into industrial automation comes with challenges. These include cybersecurity risks, the need for significant upfront investment, and the complexity of managing vast amounts of data. However, with the right strategies, these hurdles can be overcome.

Future Prospects

The future of industrial automation lies in further IoT integration. Advances in AI and machine learning will enhance IoT capabilities, leading to even smarter and more autonomous systems. The journey towards fully automated, intelligent factories is just beginning.

For more insights into the future of manufacturing, explore our industry trends section.

Conclusion

The impact of IoT on industrial automation is profound, offering both opportunities and challenges. As technology evolves, so too will the ways in which industries automate and optimize their operations. The IoT revolution in industrial automation is not just coming—it's already here.